People and Projects

Here we present what matters most: people and their projects from the makerspace.

We’re happy about every contribution we’re allowed to showcase here – because sharing knowledge is the best kind of feedback!

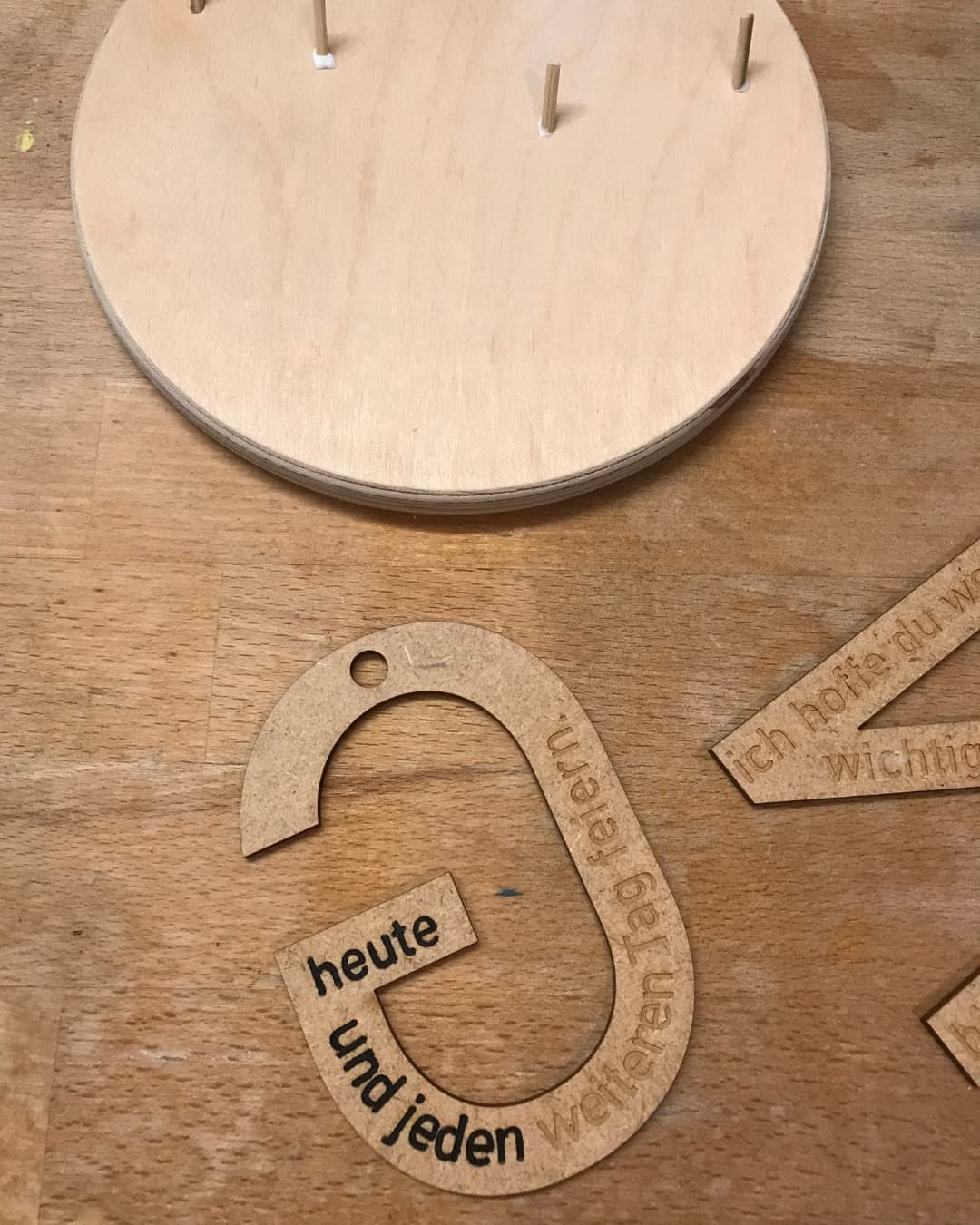

Wooden Gift Card by Viola

"The Wooden Gift Card was a spontaneous project as a birthday present for a friend. I had only recently completed the laser cutter introduction and thought it would be a great opportunity to apply my newly learned skills and experiment a bit on my own."

"First, I decided to arrange the individual letters of the name on a round wooden disc that I still had at home. Then I used the laser cutter software to position my birthday wishes on the individual letters and cut them out with the laser. I traced over the text with a black marker to make it easier to read. Using a drill, I made four small holes in the round disc and glued four short wooden skewers into them. Finally, I coated and painted everything in different colors."

Why did you choose to implement your project in the RUB Makerspace and not somewhere else?

"I don’t know any other place in Bochum besides the RUB Makerspace where I can independently carry out my projects. I think it’s great that you can use so many different tools and workshops in the makerspace, and that the staff on site support you with your ideas."

Start-up “Pavoa” Invents Tampon Dispenser

Zum Artikel "Einfach umsetzbar, schnell montiert und kontaktlos".

"Michael Schwarz invents a tampon dispenser and founds a start-up. Five dispensers have been in use since October 2022 as part of the pilot project Free Menstrual Products at RUB. [...] Alongside his studies, Michael Schwarz works in the RUB Makerspace, where he also had the opportunity to manufacture his tampon dispensers using the 3D printers."

Katrin Heyer, from the article mentioned above

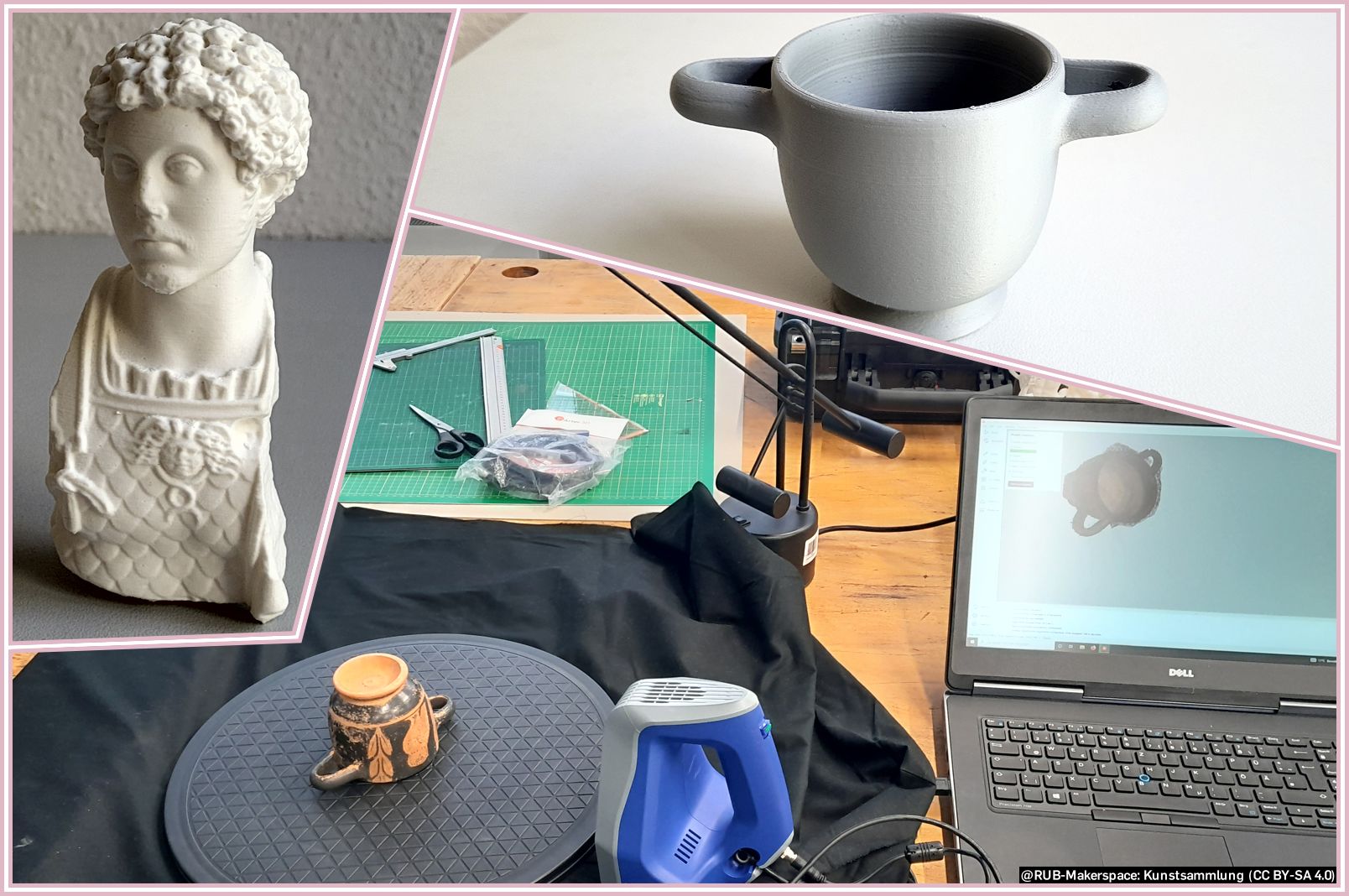

Replicating, Preserving, and Making Ancient Artifacts Tangible

Zum Artikel "Studentische Projekte in die Kunstsammlungen Antike implementiert". Zur Webseite der Kunstsammlung Antike

"Ceren Simsek, Jessica Noffc, and Robin Beuting (from left) opted to create 3D prints of busts from the Classical Antiquities Collection. The prints are durable and can also be experienced through touch by visitors. [...] In cooperation with the Makerspace, several students used the 3D printers there to produce copies of the exhibition pieces."

Katrin Heyer, from the article mentioned above

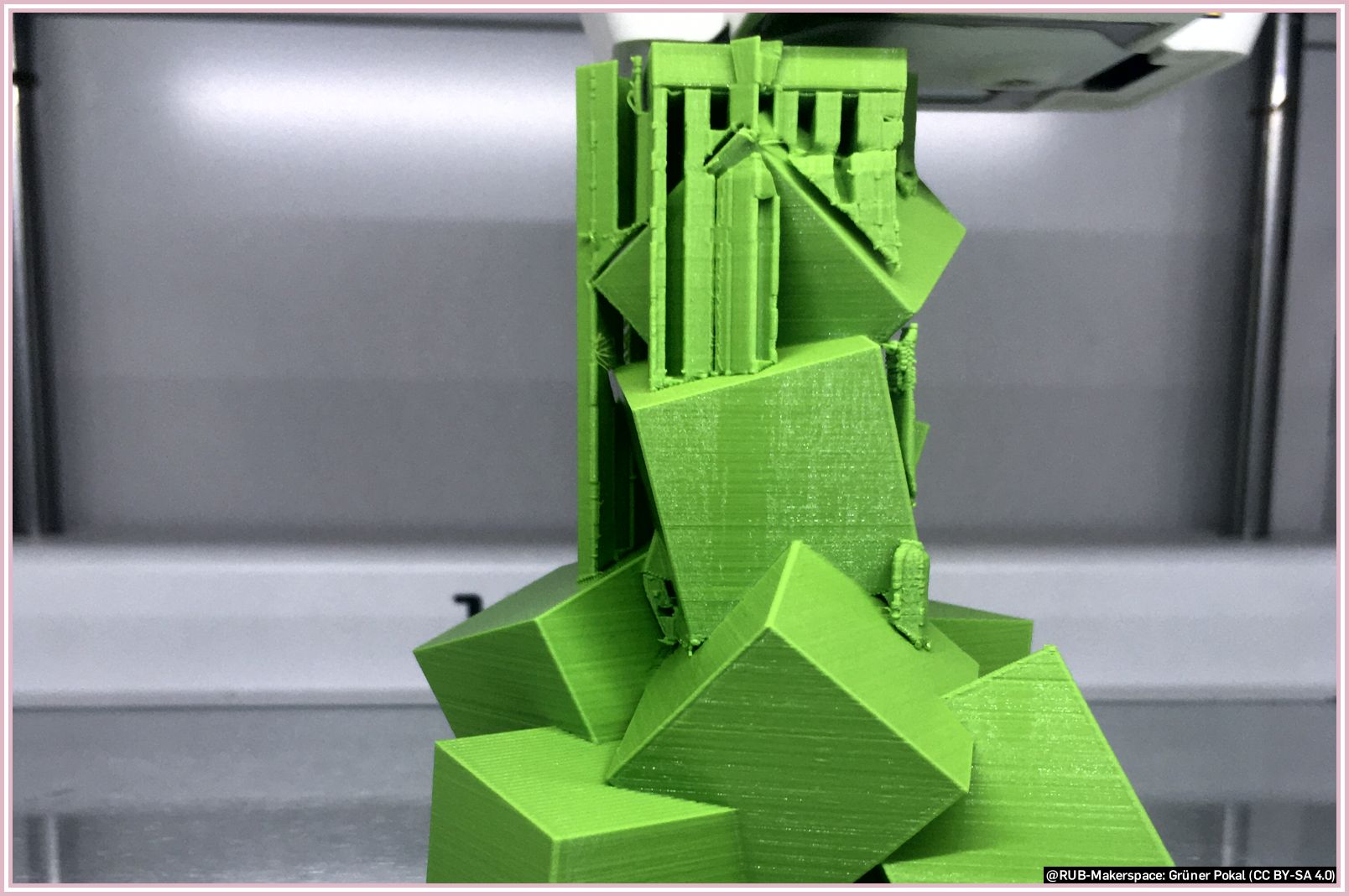

Trophy from the 3D Printer

This project shows a half-finished trophy that a group of users wanted to produce for a pitch event.

They created a CAD model on the computer and then prepared it for 3D printing using so-called slicer software.

To achieve good quality, the layer thickness was set very thin. While this increased the print time, it meant that very little post-processing was required. PLA filament was used as the material, which is standard in the FDM printing process.

If you have questions about 3D printers and slicers, the best people to ask are the team at the Rapid Prototyping Lab.

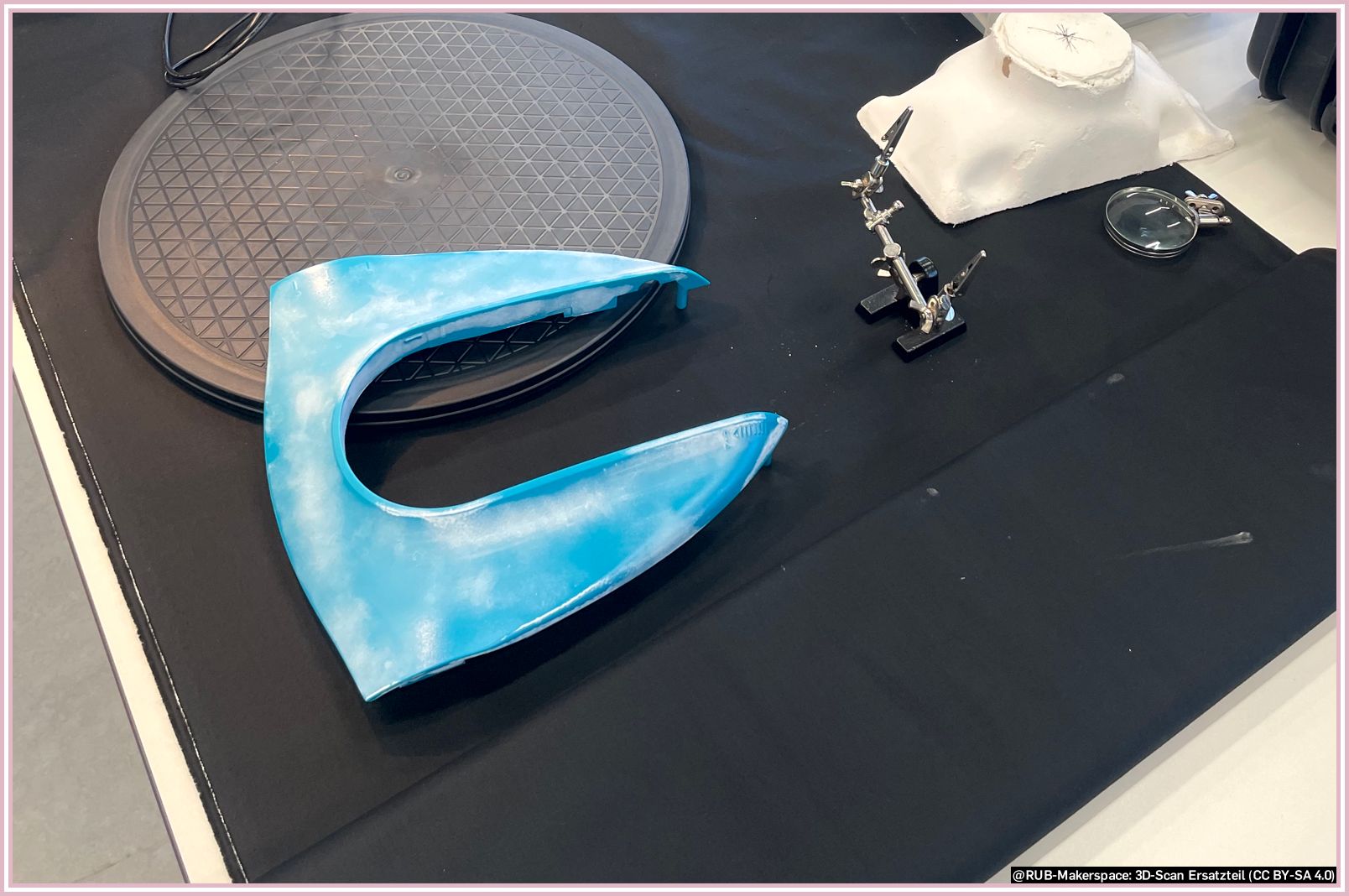

3D Scanning a Spare Part

In this case, a maker wanted to produce a replacement part for a garden device.

To do so, he brought the defective part to the RUB Makerspace and digitized it there using the 3D scanners.

To achieve better results, the part was sprayed with a matte coating spray beforehand.

The finished scan was then post-processed on the computer and finalized as a model.

If you have questions about the 3D scanners, the best people to ask are the team at the Rapid Prototyping Lab.

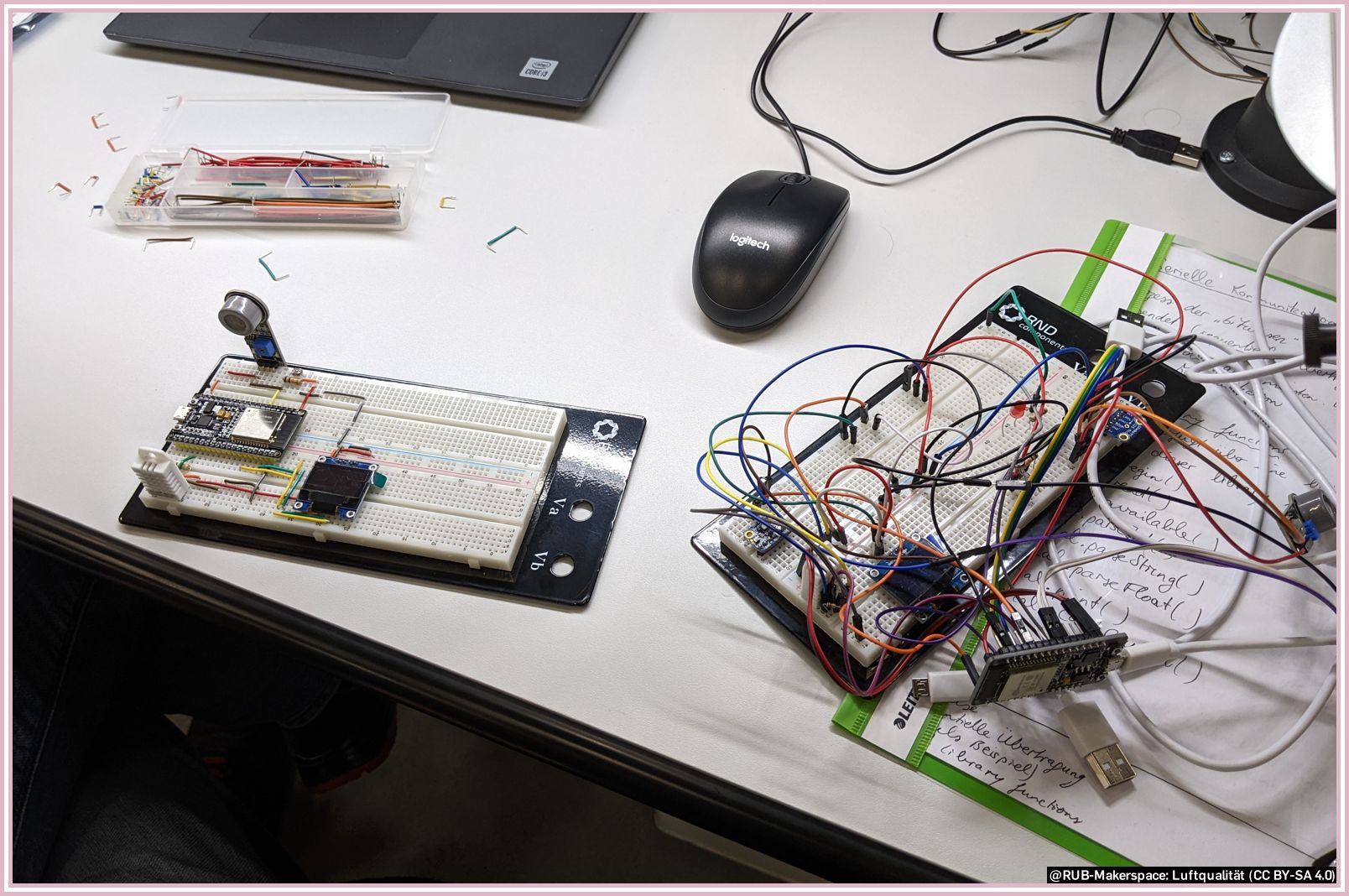

Sensors for Air Quality in the Makerspace

This project was implemented in the electronics workshop to monitor the air quality in our makerspace.

It uses a microcontroller, an air quality sensor, a display for data visualization, and additional peripherals in the form of a breadboard along with several cables and resistors.

If you have questions about working with and programming microcontrollers, the best people to ask are the team at the Digital Lab.

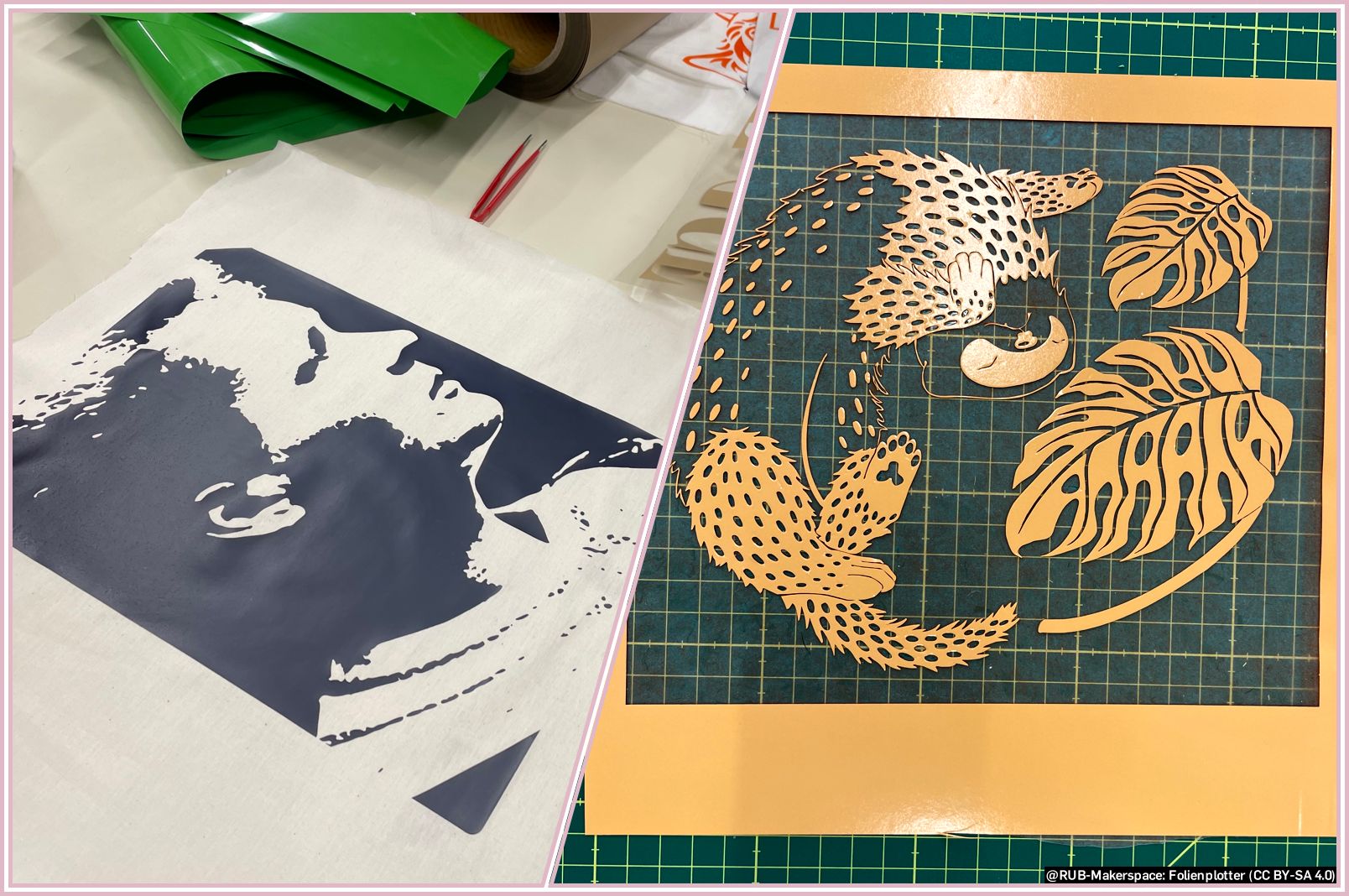

Projects with the Vinyl Cutter

These examples were created as part of a seminar and by a student intern.

In both cases, the makers used (self-created) images and converted them into vector graphics using the program Inkscape.

These vector graphics were then transferred onto heat transfer vinyl using the cutting plotter and cut out.

Afterward, excess material was removed from the designs, and they were applied to textiles using a transfer press.

If you have questions about the cutting plotter and the transfer press, the best people to ask are the team at the Rapid Prototyping Lab.

A Two-Color Scarf Knitted with Our Kniterate

This scarf was produced by a founder using the Kniterate knitting machine in our textile lab.

She used two different yarn colors and designed the patterns herself.

For this purpose, she used the software associated with the knitting machine.

If you have questions about the Kniterate, the best people to ask are the team at the Rapid Prototyping Lab.

Glaze Engraving with Our Laser Cutter

In this example, a user engraved a flowerpot using the laser cutter.

The flowerpot was mounted in a corresponding rotary attachment for this purpose.

The data was created using Inkscape. The engraving was done in the colored glaze rather than the ceramic itself.

If you have questions about the laser cutter, the best people to ask are the team at the Rapid Prototyping Lab.

Electric Guitar Body with the Shaper Origin

Building your own electric guitar — that was this maker’s goal.

With the help of our smart handheld CNC router, the Shaper Origin, he made this vision a reality.

The construction plan for the guitar came from the internet.

The vector graphic found there was edited using the program Inkscape and modified for the router.

The body was then milled in two steps, later painted, and assembled with the remaining components.

If you have questions about the Shaper Origin router, the best people to ask are the team at the Wood Workshop.

Lizenz: Creative Commons - Namensnennung - Weitergabe unter gleichen Bedingungen - 4.0 International

Quellenangabe als: "Titel, RUB-Makerspace-Team, CC BY-SA 4.0"

Für Zitate oder Material aus Fremdquellen gilt die Lizenz der Quelle.